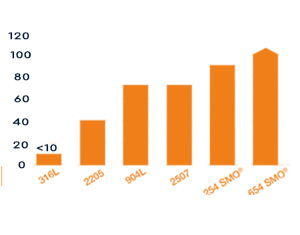

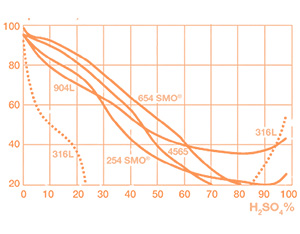

Stainless Steel 904L is an austenitic stainless steel known for its excellent corrosion resistance across a wide range of environments. Its unique combination of alloying elements provides strong protection against harsh conditions, while its austenitic structure ensures outstanding toughness and strength even at sub-zero temperatures. This makes it ideal for use in challenging industrial applications where durability and performance are crucial. Stainless Steel 904L Chemical Composition SS 904L Mechanical Properties Physical properties of INOX AISI 904L Being non-magnetic, this grade is highly formable and easy to weld, making it suitable for complex shapes and structures without compromising its integrity. It can be shaped into various forms with minimal risk of damage, ensuring high-quality end products in a variety of industries. AISI 904L Welding Process SUS 904L Mean Coefficient of Thermal Expansion As a low-carbon, high-alloy austenitic stainless steel, 904L is primarily used for its exceptional corrosion resistance. The addition of copper enhances its ability to withstand aggressive environments such as sulfuric, phosphoric, and acetic acids. It also shows high resistance to pitting and crevice corrosion in chloride solutions, along with good resistance to stress corrosion cracking. Corrosion Resistance of Alloy 904l Minimum Stress For Failure % of Rp0.2 at 200°C Typical threshold stresses determined using the drop evaporation test. Temperature, °C Isocorrosion curves 0.1 mm/year, in pure sulphuric acid. Corrosion Rates of 904L Material The high levels of chromium, nickel, and molybdenum contribute to its excellent corrosion resistance, particularly against chloride stress corrosion cracking, pitting, and general corrosion. These elements ensure that the material performs well in aggressive chemical environments. Chemical Compatibility of Stainless Steel Alloy 904L This grade is suitable for use in high-temperature environments due to its remarkable heat and corrosion resistance. It is widely used in the chemical and petrochemical industries, where materials must endure both corrosive conditions and elevated temperatures without losing structural integrity. UNS N08904 Material Temperature Range Type 904L Stainless Steel Thermal Properties Equivalent grades allow users to identify the same material in different countries, which is essential for international trade. Knowing the equivalent grade ensures that the material meets the required specifications and properties for the intended application. Understanding the chemical composition is vital in manufacturing stainless steel, as it determines the material’s mechanical properties, including strength, toughness, and ductility. This helps the product withstand corrosive or harmful conditions effectively. Specifications provide standardized information on the material's properties, helping users determine where and how it can be applied. This ensures that the material is used appropriately in different industrial settings. AISI 904L Equivalent Grades Specifications of SUS 904L Material SAE 904L Electrical Properties DIN 1.4539 Applications Advantages & Disadvantages of SS 904L Material Advantages Disadvantages Hot Forming of SUS 904L Cold Forming of SS 904L Machining of Stainless Steel Alloy 904L

we are regular Trigger Sprayer,trigger spray head manufacturer ,with high quality control.

Normally used for window cleaning,car wash bottle sprayer,hair care sprayer,house cleaning, laundry care, & pet training.etc.

with adjustable spray/stream nozzle,foam nozzle,

There are 28/400 28/410 28/415 ratchet standard size ,with screw closure to fit with bottles.

Regular Trigger Sprayer,Trigger Spray Head,Spray Nozzle Trigger,Water Spray Nozzle Trigger For Bottle NINGBO CRETE PLASTIC CO.,LTD , https://www.crete-sprayer.com

Table of contents

Grade

Yield Strength 0.2% Proof (MPa) min

Tensile Strength (MPa) min

Elongation (% in 50mm) min

Hardness

Brinell (HB)

Rockwell B (HR B)

904L

220

490

36

150

70-90 typical

Density

kg/dm³

8

Modulus of elasticity

GPa

195

Thermal Capacity

J/kg°C

450

Electrical resistivity

µΩm

1

Thermal conductivity

W/m°C

15.8

Alloy 904L Offers Excellent Formability and Weldability

Yield Strength 0.2% Offset psi (MPa)

Ultimate Tensile Strength psi (MPa)

Hardness

Elongation in 2 in. %

31,000

220

71,000

490

70 – 90 Rockwell B

36

1.4539 Material is Known for Its Corrosion Properties

Uniform corrosion

Corrosion, (mm/year)

pickling acid at 25°C

0.47

wet process Phosphoric acid at 60°C

1.2

Distillation of Tall oil at 253°C

0.06

SUS 904L Has High Concentrations of Chromium, Nickel and Molybdenum

Chemical

Compatibility

Sulfuric Acid (Hâ‚‚SOâ‚„)

Good resistance ; avoid concentrated acid.

Hydrochloric Acid (HCl)

Better resistance compared to many other stainless steels, especially at lower temperatures.

Nitric Acid (HNO₃)

Good resistance, particularly up to 65% concentration at room temperature.

Phosphoric Acid (H₃PO₄)

Good performance in moderate concentrations and temperatures.

Sodium Hydroxide (NaOH)

Resistant, especially in lower concentrations

Sodium Chloride (NaCl)

Resistant but prone to stress corrosion cracking in high chloride environments.

Acetone

Generally compatible.

Ethanol

Generally compatible.

Formic Acid

Shows good resistance.

Oxidizing Agents

Resistant to many oxidizing agents.

Hydrogen Sulfide (Hâ‚‚S)

Susceptible to stress corrosion cracking, especially under high temperature.

SS 904L is Heat Resistant Alloy Designed for High Temperature Structural Applications

Temperature Range

Performance

Cryogenic Temperatures (< -200°C / -328°F)

Generally suitable

Ambient to Moderate Temperatures (up to ~400°C / 750°F)

Excellent performance

High Temperatures (~400°C to 800°C / 750°F to 1470°F)

Capable of withstanding moderate temperatures

Exceeding 800°C / 1470°F

The material is generally not recommended for such high temperatures.

Thermal Properties

Metric

English

CTE, linear

15.3 µm/m-°C

Temperature 20.0 – 100 °C8.50 µin/in-°F

Temperature 68.0 – 212 °F

16.5 µm/m-°C

Temperature 20.0 – 400 °C9.17 µin/in-°F

Temperature 68.0 – 752 °F

18.2 µm/m-°C

Temperature 20.0 – 800 °C10.1 µin/in-°F

Temperature 68.0 – 1470 °F

Specific Heat Capacity

0.460 J/g-°C

0.110 BTU/lb-°F

Thermal Conductivity

11.5 W/m-K

Temperature 20.0 °C79.8 BTU-in/hr-ft²-°F

Temperature 68.0 °F

12.9 W/m-K

Temperature 100 °C89.5 BTU-in/hr-ft²-°F

Temperature 212 °FRefer 904L Material Equivalent, Composition and Specification

Grade

UNS No

Old British

Swedish SS

Euronorm

En

BS

No

Name

904L

N08904

–

904S13

2562

1.4539

X1NiCrMoCuN25-20-5

Electrical Properties

Metric

English

Electrical Resistivity

0.0000952 ohm-cm

0.0000952 ohm-cm

Magnetic Permeability

<= 1.02

<= 1.02

904L stainless steel material

Carbon (C)

0.02

Manganese (Mn)

2.00

Phosphorous (P)

0.03

Chromium (Cr)

19.00 – 21.00

Nickel (Ni)

24.00 – 26.00

Molybdenum (Mo)

4.00 – 5.00

Copper (Cu)

1.20 – 2.00